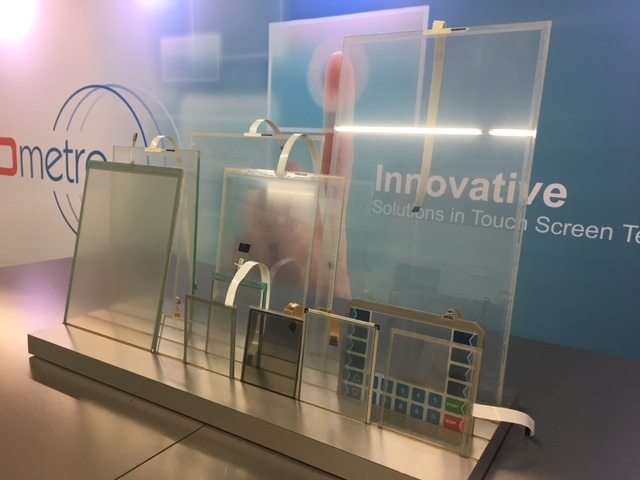

Touch screen solutions that are available in a wide range of standard sizes and formats; and can also be custom manufactured to individual clients requirements.

Our touch screen sensors and controllers are used extensively for control panels, monitors, all-in-one computers, kiosks and portable mobile computing device applications. Touch screen applications that are deployed across a diverse range of markets including aerospace, industrial, retail, marine, military, transportation, healthcare and medical.

Understanding touch screen technologies and the differences between them is important when contemplating design options and trade-offs.

1390 Star Top Rd.

Ottawa, Ontario, Canada K1B 4V7

Sales: sales@admetro.com

Support: support@admetro.com

1 800 463 2353 (US & Cnd)

Tel: +1 613 742 5545

Fax: +1 613 742 5245

Hours of operation:

Monday to Friday, 9am to 5pm EST

Copyright © 2025 A D METRO INC., ALL RIGHTS RESERVED.