A D Metro has been designing and manufacturing resistive touch sensors since 1995. This extensive experience has been incorporated into today’s designs, using advanced materials to produce the most reliable and cost effective resistive touch screen sensors available on the market.

A D Metro stands behind these high quality resistive touch sensors that target the most cost-sensitive applications.

Sensors include 5-Wire models that deliver reliability and longevity well beyond expectations. 5-Wire sensors are substantially less prone to the main mechanism of degradation of traditional resistive touch sensors – micro-cracking of the top layer of transparent conductive material (indium tin-oxide).

Two-Touch functionality is available for our 1.85 mm and 2.85 mm ITO substrate glass, 5-wire ULTRA resistive sensors up to 21.3” in size with 0.1 mm ULTRA microglass, or up to 15.5” in size with 0.145 mm ULTRA microglass.

Please refer to our Resistive Sensor Catalog to identify these sensors.

Should you have any questions regarding our products, please do not hesitate to get in touch.

| Size: | 3.5″ to 24″ |

| Types: | 5-wire, 4-wire or 8-wire |

| Input Device: | Finger, Stylus, Gloved finger |

| Activation Force: | <60 grams |

| Surface Hardness: | 3H Pencil |

| Temperature: | Operating: -10°C to +55°C* Storage: -40°C to +70°C* |

| Enclosure Compatibility: | NEMA 4, 12; IP65 |

| Transmittance: | ≥84% |

Some applications have more demanding requirements. To meet these needs A D Metro can make select combinations of the following enhancement options available:

Please refer to the Resistive Sensor Catalog for specific details.

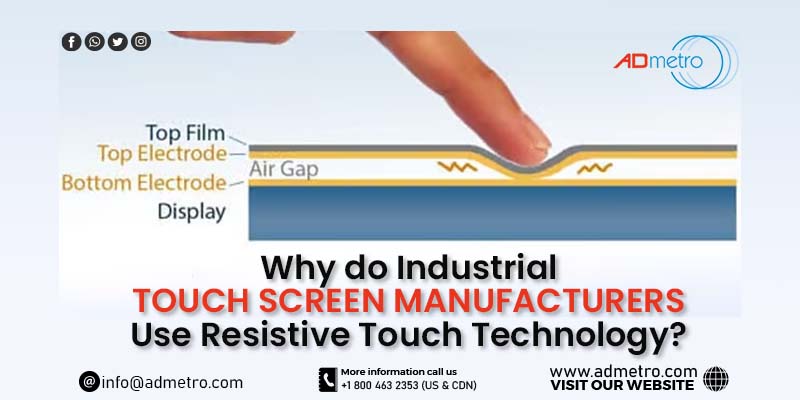

A resistive touch screen sensor is an analogue switch technology that is pressure activated. Two conductive coated layers (usually using Indium Tin Oxide [ITO]), facing each other, are separated by a layer of dielectric spacer dots. When pressure is applied to the top surface, the two layers come into contact and the controller locates the touch point. To determine the x and y coordinates, in 4- and 8-wire sensors a voltage gradient is applied to each layer in turn; and in 5-wire sensors the resistance is measured between the top layer and each of the four corners of the base layer.

For more information on popular touch screen technologies, please download our whitepaper.

1390 Star Top Rd.

Ottawa, Ontario, Canada K1B 4V7

Sales: sales@admetro.com

Support: support@admetro.com

1 800 463 2353 (US & Cnd)

Tel: +1 613 742 5545

Fax: +1 613 742 5245

Hours of operation:

Monday to Friday, 9am to 5pm EST

Copyright © 2025 A D METRO INC., ALL RIGHTS RESERVED.