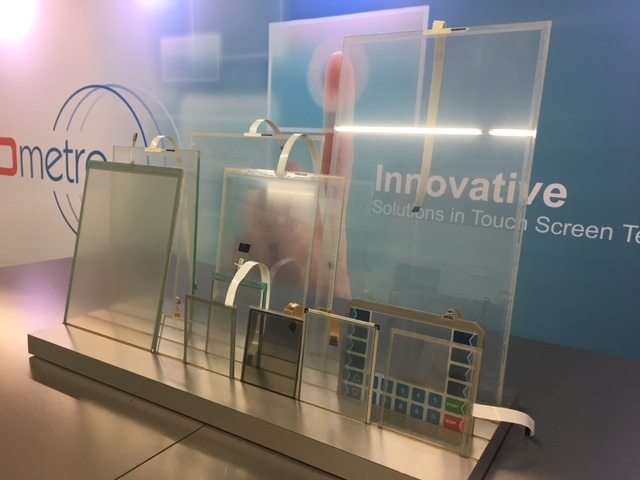

Choose either our conventional, standard resistive sensors or our patented ULTRA armored resistive sensors. ULTRA sensors are proven in the most physically demanding touch applications. An extensive range of 4-wire, 5-wire and 8-wire resistive sensors are available in either style.

A D Metro’s resistive touch products include a range of trusted and advanced controllers.

Our most popular 1-touch controller variant supports 4-wire or 5-wire resistive sensors and communicates through a standard USB interface. Other variants in this series attach to sensors using latching connectors specific to 4-wire, 5-wire or 8-wire sensors. There are further variants easily configurable to communicate either through USB or full voltage RS-232.

Our patented 2-touch resistive controller works with a range of unmodified 5-wire ULTRA or standard resistive controllers. Its unique 2-touch capability delivers pinch/zoom/rotate operations 5-wire resistive sensors through a standard multitouch USB interface.

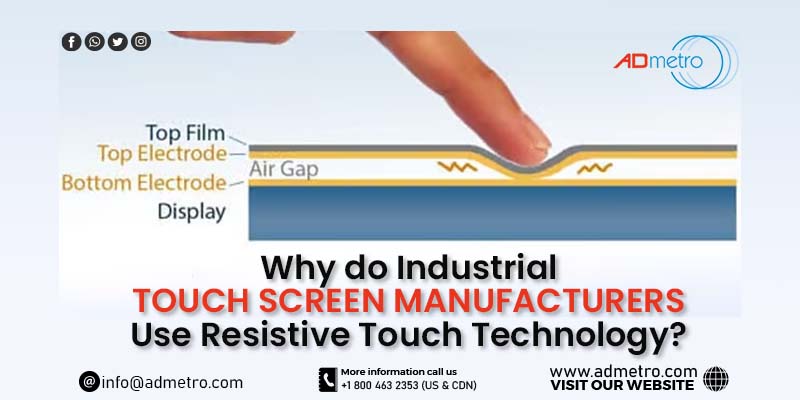

A resistive touch screen sensor is an analogue switch technology that is pressure activated. Two conductive coated layers (usually using Indium Tin Oxide [ITO]), facing each other, are separated by a layer of dielectric spacer dots. When pressure is applied to the top surface, the two layers come into contact and the controller locates the touch point. To determine the x and y coordinates, in 4- and 8-wire sensors a voltage gradient is applied to each layer in turn; and in 5-wire sensors the resistance is measured between the top layer and each of the four corners of the base layer.

For more information on popular touch screen technologies, please download our whitepaper.

1390 Star Top Rd.

Ottawa, Ontario, Canada K1B 4V7

Sales: sales@admetro.com

Support: support@admetro.com

1 800 463 2353 (US & Cnd)

Tel: +1 613 742 5545

Fax: +1 613 742 5245

Hours of operation:

Monday to Friday, 9am to 5pm EST

Copyright © 2024 A D METRO INC., ALL RIGHTS RESERVED.