A D Metro’s patented ULTRA touch screen, with its armor glass surface, is the most durable, reliable and economic resistive touch screen sensor on the market.

What differentiates ULTRA is its patented durable glass surface that is scratch, abrasion and chemical resistant. It combines the characteristics of a durable glass surface with the benefits of a resistive touch screen. ULTRA offers performance characteristics that are ideal for wide range of commercial, industrial and military applications where rugged durability and reliability are required.

ULTRA overcomes the traditional limitations of standard resistive touch screen sensors with its durable borosilicate glass surface, rather than the standard traditional polyethylene surface. The hard glass surface is resistant to scratches and abrasion, impervious to most chemicals and waterproof. Its glass surface is suitable for IP67 and NEMA 6 enclosures. As a pressure activated touch screen it can be reliably operated by finger, any glove or stylus; and even with contaminants on the screen, such as rain, oil, grease, food, dirt and dust. ULTRA’s construction allows it to be used over an extended range of operating environments; and it offers unparalleled reliability, that has been tested to over 200 million operations. These characteristics make ULTRA ideal for reliable operation in harsh environments including rugged, outdoor and unattended kiosk applications.

Ultra offers easy integration into many applications. Its immunity to EMI enables easy integration with any type of display and without compromising touch sensitivity. Its compatibility with standard resistive controllers, offering USB-HID support, enables rapid product development and accelerates time to market.

For less demanding applications see A D Metro’s Standard Resistive touch screen sensors.

Two-Touch functionality is available for our 1.85 mm and 2.85 mm ITO substrate glass, 5-wire ULTRA resistive sensors up to 21.3” in size with 0.1 mm ULTRA microglass, or up to 15.5” in size with 0.145 mm ULTRA microglass.

Please refer to our Resistive Sensor Catalog to identify these sensors.

Should you have any questions regarding our products, please do not hesitate to get in touch.

| Size: | 3.5″ to 24″ |

| Types: | 5-wire, 4-wire or 8-wire |

| Input Device: | Finger, Stylus, Gloved finger |

| Activation Force: | <80g |

| Surface Hardness: | 6.5 Mohs |

| Temperature: | Operating: -35°C to +80°C* Storage: -40°C to +85°C* |

| Enclosure Compatibility: | NEMA 4, 6, 12 IP65, IP67 |

| Transmittance: | ≥84% |

| Sensor Lifespan (Touches): | 5-wire: >200 million 4/8-wire: > 20 million |

*Technical specifications apply to standard products and are subject to change without notice. Product performance will be subject to suitable installation and mounting. Consult manufacturer for technical drawings, best practices for installation and mounting, confirmation that product can meet intended application’s requirements or for the applicable product specifications when optional enhancements are applied.

Some applications have more demanding requirements. To meet these needs A D Metro can make select combinations of the following enhancement options available:

Please refer to the Resistive Sensor Catalog for specific details.

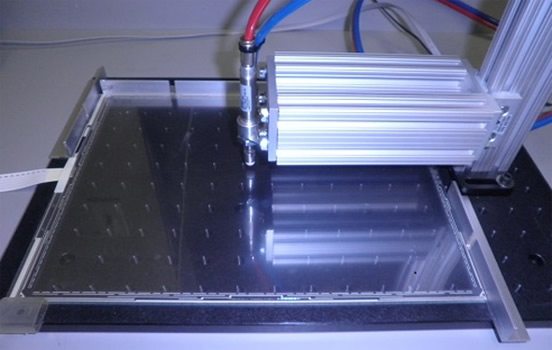

The 5-wire ULTRA resistive touch screen sensor has been tested beyond 200 million touch operations on a single point with a “Thumper Test” and without any failure of the sensor.

An ULTRA resistive touch screen sensor works in the same way as a resistive touch screen sensor. A resistive touch screen sensor is an analogue switch technology that is pressure activated. Two conductive coated layers (usually using Indium Tin Oxide [ITO]), facing each other, are separated by a layer of dielectric spacer dots. When pressure is applied to the top surface, the two layers come into contact and the controller locates the touch point. To determine the x and y coordinates, in 4- and 8-wire sensors a voltage gradient is applied to each layer in turn; and in 5-wire sensors the resistance is measured between the top layer and each of the four corners of the base layer.

For more information on popular touch screen technologies, please download our whitepaper.

1390 Star Top Rd.

Ottawa, Ontario, Canada K1B 4V7

Sales: sales@admetro.com

Support: support@admetro.com

1 800 463 2353 (US & Cnd)

Tel: +1 613 742 5545

Fax: +1 613 742 5245

Hours of operation:

Monday to Friday, 9am to 5pm EST

Copyright © 2025 A D METRO INC., ALL RIGHTS RESERVED.