Touch screen technology has taken a big leap in terms of facilitating the best user experience. This has become possible with several different options of touch screens available on the market, fulfilling the requirements of diverse applications. A widely used type is resistive touch screens which is a conventional touch solution used in the industry for decades. Most importantly, the advancements and innovations in resistive touch technology have made still a good choice even today.

Here are some of the top reasons for using resistive touch screens for many applications. The last reason is the most important of all.

Enclosure Compatibility for Easy Integration

Resistive touch screens offer great compatibility with industrial applications. They are best suited to NEMA 12/4/4X and IP65/66 enclosure standards, enabling the equipment to withstand environmental exposure. It doesn’t require too much effort to properly seal the touch screen in the bezel of a display. A compressible foam gasket is normally used.

Pressure Activated Controls for Seamless Operations

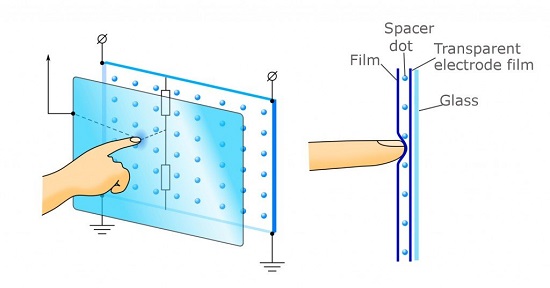

Another reason that makes resistive touch screens the right fit for several industrial applications is the activation mode. Resistive touch technology is pressure activated. The pressure exerted against the sensor’s surface enables the sensor to register the touch command. So the work efficiency improves with resistive touch display applications used for control panels. They are especially, helpful in industries where workers have to wear heavy safety gloves. Control panels with resistive touch display can be operated with bare fingers, gloved hands or any type of stylus.

Economical Option for Development & Maintenance Touch

The cost of building and maintaining applications matters a lot, and resistive touch screens offer the most economical solution in this regard. These are easy to integrate and relatively cheaper than other touch screen solution. As a result, the development costs of applications can be significantly lower.

ULTRA-Resistive Option to Overcome Drawbacks of Standard Resistive

The only challenge of using resistive touch screens is the durability and waterproof capability. Typically, standard resistive touch screens have a PET surface layer. To overcome these challenges and offer a much more durable solution, A D Metro has developed ULTRA resistive touch screen sensors, offering the coveted durability combined with the benefits of resistive touch screens. The ULTRA armored resistive touch screens are designed from patented durable glass surfaces that allow applications to withstand rugged environments and maintain flawless operations. They are waterproof, scratch, abrasion and contamination resistant.

ULTRA resistive touch screens are available with a variety of enhancement options to meet industry-specific demands. The provided enhancements by A D Metro include Alternative Thicknesses of Borosilicate Glass, Anti-Glare (AG) Coating, Anti-Reflective (AR) and Hydrophobic coatings, Foam or Adhesive Mounting Gaskets, Chemically Strengthened Backer, Polycarbonate Substrate, and Graphic Underlay (Printed Laminations).