Fuelled by the evolution in technology, at present, a wide range of options are available for touchscreens. Thus, when it comes to choosing the one, the decision entirely depends on the convenience it can add to the device usage.

However, a large number of industries prefer resistive touchscreens for their application. It offers multiple benefits, cost-effective and multi-touch operation ability (gloved and bare finger and stylus), are some of them.

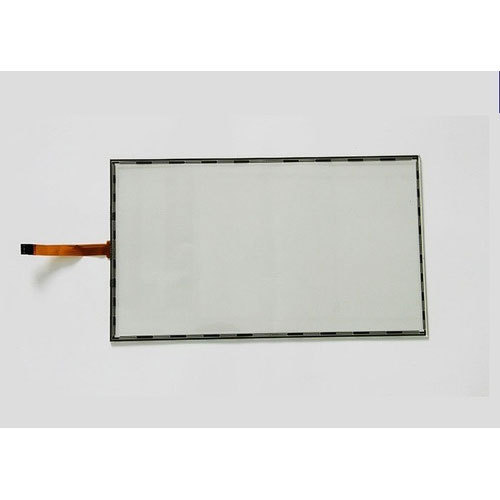

Talking about the internal structure of a resistive touchscreen, it comprises two layers of glass and film, coated with a transparent conductive material both of which are separated by an air gap and microdots. When the flexible top/ front layer is pressed, the two layers come in contact with each other, and the voltage at the point of contact is read through conductors at the edges of each layer in the case of 4-wire or just the bottom layer in the case of a 5-wire. The voltage read at the touch point determines the location of the touch point.

Further, based on design, the two most common types of resistive touchscreens we have, are 4-wire resistive touchscreens and 5-wire resistive touchscreens.

If you are considering a resistive wire touchscreen, but confused with the design, here are the subtle nuances that can help you understand the difference between the 4 and 5 wired resistive touchscreens.

4-wire resistive touchscreens

In 4-wire resistive touchscreens, Each of the two layers has a conductive buss bar printed along two opposite edges. One layer will have buss bars located top and bottom with the other layer having buss bars located on the left and right edges. The controller will apply a DC voltage across one of the layers with the positive connected to one bar and the negative connected to the other. This will create a voltage flow through the conductive coating of that layer that varies in voltage level depending on how close it is read to either the positive buss bar or the negative buss bar. When a touch event occurs, the opposite layer comes in contact with the voltage layer and the controller uses the opposite layer as a voltage probe to read the voltage at the touch point. The controller can then determine where the touch point is in that one plane (either X or Y). To get the other plane, the controller flips the functions of the layers so that the same happens but in X rather than Y or vice versa. This flipping of layer functions happens typically more than 100 times per second, so the X and Y coordinate readings have no lag in reporting.

The benefit you can have with 4-wire resistive touchscreens is the cost-effective solution it offers. It consistently remains the cheapest touch panel for low end applications. .

5-wire resistive touchscreens

5-wire touchscreens measure voltage from the lower layer only. Unlike 4-wire resistive touchscreens that use both layers to measure voltage, in a 5-wire touchscreen, the upper layer is simply a voltage probe that is used only to measure the voltage of the bottom layer. Like the 4-wire, the 5-wire measures voltage in one plane then flips the voltage application to the other plane but it is done only on the bottom layer which has a special conductor pattern around the perimeter that allows for this function the be carried out on the one layer. It means the micro-damage to the upper no load voltage probe layer won’t obstruct the touchscreen’s performance or accuracy.

The reasons why 5-wired touch panels are preferred for commercial applications over 4-wire resistive touchscreens, are that 5-wire models are more durable, accurate and long-lasting.

Though it costs slightly more, 5-wire resistive touchscreen is an investment that can pay off in the long run.

Final Words!

With A D Metro, you can get both- durable and cost-effective resistive touchscreens with different enhancements to meet the more demanding requirements of several applications. The resistive touchscreens from A D Metro, include 4 and 5 wire, and are resistant to contamination and offers great sealable compatibility with NEMA 4, 12 and IP65 enclosures. A D Metro also offers their flagship armoured resistive version called ULTRA which offers many more benefits over standard resistive including a 10-fold increase in life expectancy.