Resistive touchscreens have remained a leading touch sensor technology for over 40 years. They offer economical touchscreen solutions featuring two layers of electrically resistive material separated by spacer dots. With a tap or touch command on the display surface, the two layers come in contact resulting in the detection of touch inputs. Out of the different resistive touchscreens, 5-wire is the most widely used.

Here are the basics of 5-wire resistive touchscreens.

5-wire resistive touchscreens are the advanced version of resistive touch sensors that use a specific configuration of electrodes- an essential component to detect touch commands. Unlike its counterpart – 4-wire and 8-wire, which have opposing pairs of conductive X and Y buss bars, 5-wire resistive touchscreens utilize electrodes placed on the four corners of the substrate layer.

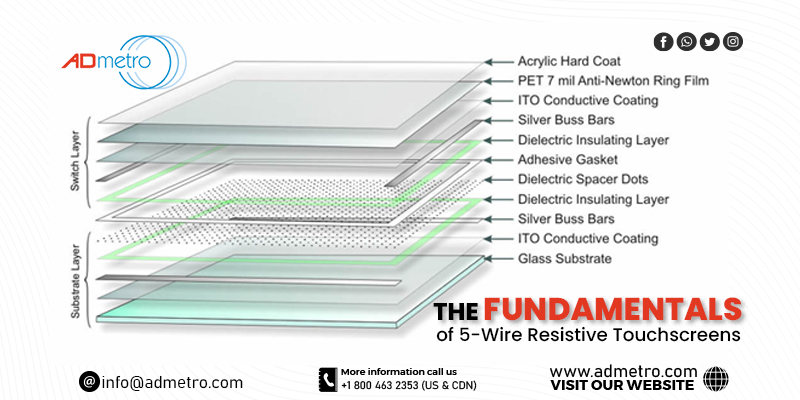

The 5-wire resistive touchscreen technology has transparent conductive coatings on the inside of both the top and bottom layers, separated by tiny spacer dots. The four electrodes at the corners of the bottom conductive layer are connected to the flexible circuit tail of the sensor. The top layer is connected with just one wire and used as a voltage probe for the sensor. When pressed by touch, it sends the voltage in alternating X and Y planes to the controller and the touch coordinates are then calculated.

This unique configuration makes 5-wire resistive touchscreens preferred over other touchscreen technologies.

Why Choose 5-Wire Resistive Touchscreens?

Durability is a significant feature required in a touch application. Resistive touchscreens are known for durability; however, 5-wire technology offers the highest durability of all.

The sensor life of 5-wire resistive touchscreens is comparatively more than 4-wire, which doesn’t have good sensor life. A 4-wire sensor can get damaged by only a few hard strokes of a fine point stylus and typically offers 4 million touches or less on the same spot with finger operation. The 5-wire touch sensor, on the other hand, is not affected much by ITO fracturing because it does not need to maintain actual values of current flow to remain linear. 5-wire resistive touch sensors can achieve 35 million touches on the same point with finger activation.

5-wire resistive touchscreens are relatively sensitive. It means there’s no need to press it hard or forcefully to register touch commands. They require light-pressure touch with a physical object to register the input.

5-wire resistive touchscreens can be operated using any physical object- a bare finger, a gloved finger or a stylus. They do not depend on human capacitance to register touch commands such as with capacitive touch screens.

However, there are graphical user interfaces (GUIs) in applications facing challenging environments that only resistive touch sensors can endure. At the same time, they also demand multi-touch capability, which is typically unavailable in standard resistive touchscreens.

To overcome this limitation, A D Metro has elevated the feature of standard 5-wire resistive sensors through their advanced two-touch resistive touchscreen controller. This controller delivers the two-touch capability to 5-wire resistive touch sensors.

A D Metro’s two-touch 5-wire resistive touchscreen controller offers 100 touch points per second for single touch and for multi-touch -70 touch points per second, allowing fast and smooth touch operations. Through this innovative multi-touch solution, 5-wire resistive touchscreens can be made capable of two-touch operation along with pinch, zoom, rotate and drag gestures. Furthermore, the two-touch controller allows HID plug & play in Windows to assist in seamless integration.

Overall, A D Metro’s two-touch controller delivers new capabilities to the reliable, tried and tested 5-wire resistive touchscreens.